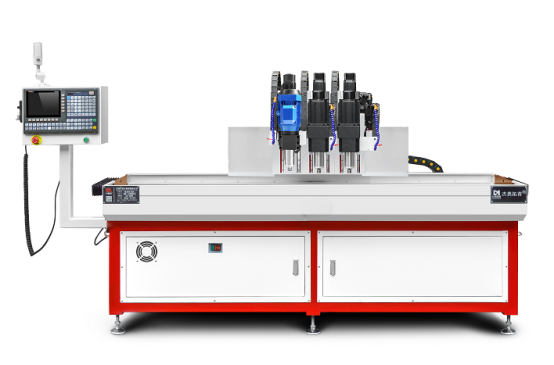

Today to introduce a three-spindle flow drilling and chamfering machine, three spindles can be installed with three different tools, dot, chamfering, hot melt bit, extrusion tapping, flow drilling and chamfering machine can also be installed with ordinary twist drill and cutting tap, three processes or three different bore can be processed at the same time. At the same time, we can also customize multiple spindles according to customer's product processing requirements.

The one on the side of the spindle is a circulating cooling spray pipe, and this flow drilling and tapping chamfer machine we also have an oil spray atomization device with company oil, that is, the oil it sprits out has been atomized, which is better for the cleaning of the product surface.

In terms of fixtures, our flow drilling and chamfering machine is also left and right double station cycle processing.

Between the flow drilling and chamfer machine, in order to eliminate an accumulated error in the shape of the product, we have made a positioning block between each product in the simplex, that is, here, and here, it can be positioned separately before and after each product, and then the fixture takes a cylinder before and after the top.

In addition, between each station of the flow drilling and champhering machine, we have added a set of safety grating protection, while loading and unloading non-stop cycle processing, with other mechanical protection to achieve artificial safe and efficient processing.

Source of this article: http://www.duomicnc.com/