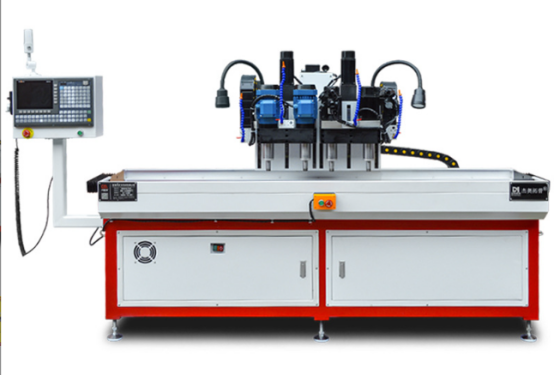

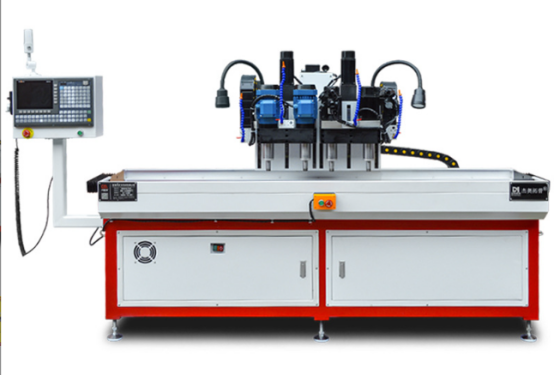

It is also a CNC four-spindle drilling and tapping machine customized according to customer requirements, the customer is to do profile aluminum. At present, customer use the multi-axis machine processing, but the variety of products is more and more, taking into account the versatility of the machine tool, the customer asked us to customize a device that takes into account the efficiency but also the operation is slightly simpler.

Because the customer's products are within 150mm in size, so we customized a CNC four-spindle drilling and tapping machine for him this time, and the double spindle is a machine with 200mm spacing. Two drilling spindles, two tapping spindles, the two products on the left are processed at the same time, and then when the spindle is moved to the right, the two products on the right can also be processed at the same time, so that you can do a non-stop cycle.

Then I will turn on the CNC four-spindle drilling and tapping machine, and we will demonstrate an effect of double-station processing.

Source of this article: http://www.duomicnc.com/