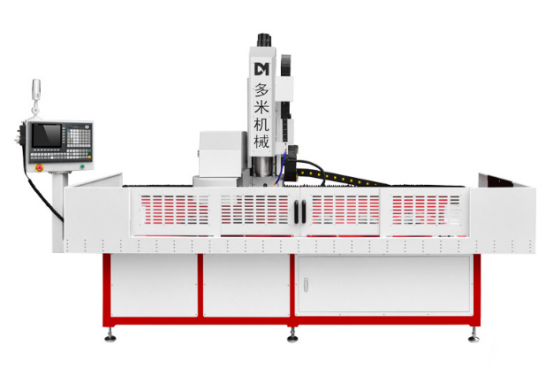

This is our automatic tool change CNC drilling and tapping machine, and today we mainly talk about its tool library and machine rigidity.

Compared with some other row type tool change models, the tool library of this automatic tool change CNC drilling and tapping machine is more advantageous. When our spindle moves long distance from left to right, if the tool library is still placed on the side of the workbench, it will extend the time to change the tool and affect the processing efficiency.

The tool library of this automatic tool changing CNC drilling and tapping machine moves with the spindle, and the servo directly connects the tool changing action. When the spindle is in the travel range, the tool can be changed at any place, which greatly improves the efficiency of the tool changing.

At the same time, because our automatic tool change CNC drilling and tapping machine stroke is relatively long, and then many customers will do left and right double station, even multi-station processing. If such a tool library is selected, workers will not be affected by the tool change action when loading or unloading, which greatly improves the safety of production and processing efficiency.

As for the rigidity of the CNC drilling and tapping machine with automatic tool change, the machine uses thickening and heavy base, passes through large-scale CNC three times finishing treatment, and then the whole machine is tempered to remove stress.

In addition, when we install the guide rail, the top block is also evenly installed on both sides of it, which plays a certain supporting role. Regarding customer selection, whether it is multi-spindle, or automatic tool changing machine tools, we will recommend suitable models to customers according to their products and give some reasonable suggestions.

Source of this article: http://www.duomicnc.com/