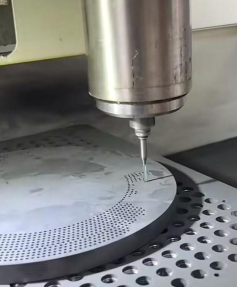

In the current production process, the micro-hole CNC drilling machine is working efficiently, precisely drilling a piece of graphite material with a thickness of 12 mm. The drilling diameter is set to 1.8mm, with advanced micro-hole CNC drilling machine and superb technology, the processing efficiency reaches every 3 seconds to complete a hole, fully demonstrating the efficiency and stability of the production process.

Because of its unique physical properties, graphite materials are widely used in many industrial fields. However, the processing process often faces a key problem - surface peeling phenomenon. This problem not only affects the appearance quality of the product, but also may have a potential impact on subsequent performance. Therefore, customers are extremely concerned about the effect of processing in the use of micro-hole CNC drilling machines.

It is gratifying that the graphite material processed by the micro-hole CNC drilling machine performs well. After strict quality control and process optimization, there is no delamination phenomenon on the surface of the material, and the overall surface finish is very high, showing excellent processing quality. This not only benefits from the advanced micro-hole CNC drilling machine, but also depends on the precise control and continuous optimization of the process parameters by the professional team.

From the overall effect point of view, the use of micro-hole CNC drilling machine drilling hole graphite material not only to achieve high efficiency production goals, but also to achieve high standards in quality. This not only provides customers with a reliable processing guarantee, but also lays a solid foundation for the further expansion of graphite materials in high-end applications.

Source of this article: http://www.duomicnc.com/