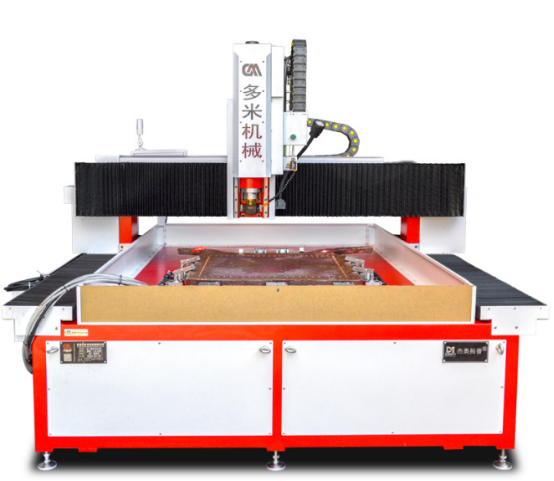

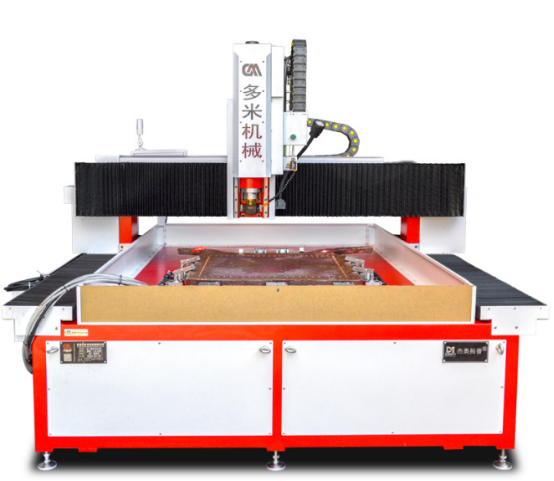

In the modern manufacturing industry, gantry CNC drilling machine is widely used in the processing of various complex workpieces because of its excellent stability and high-precision processing ability. Especially when dealing with high-precision and high-demand non-standard equipment fixtures, its performance is particularly important. This paper will introduce the application and technical requirements of gantry CNC drilling machine in machining screen display equipment fixture in detail.

First of all, when the gantry type CNC drilling machine processes the non-standard fixture of the screen display equipment, the aperture that needs to be processed is 0.3 mm, the drilling depth is required to be 2.5 mm, and the actual processing depth may reach 3.0 mm. This small aperture and deep drilling depth put high demands on the accuracy and stability of the equipment. With its strong rigidity and good stability, the gantry CNC drilling machine can effectively ensure the accuracy and consistency of the drilling and avoid the processing error caused by equipment vibration or offset.

Secondly, processing efficiency is also an important indicator to measure the performance of gantry CNC drilling machine. In the above processing tasks, the processing time of each hole is controlled within 11 seconds, which not only requires the equipment to have the ability to respond quickly and process at high speed, but also requires it to maintain stable performance under high intensity continuous operation. By optimizing the transmission system and control system, the gantry CNC drilling machine realizes the efficient and stable processing process and significantly improves the production efficiency.

In addition, the gantry type CNC drilling machine must ensure high reliability in the processing process, especially in the continuous processing of multiple holes, which is not allowed to break the bit. This requires the equipment to have accurate tool management and fault diagnosis functions, which can monitor the tool status and processing process in real time, discover and deal with potential problems in time, and ensure the continuity and safety of the processing process.

In summary, the gantry CNC drilling machine shows its excellent performance in high precision, high efficiency and high reliability when processing non-standard fixtures of screen display equipment. With the continuous improvement of processing accuracy and efficiency requirements in the manufacturing industry, gantry CNC drilling machines will play an important role in more high-precision processing fields.

Source of this article: http://www.duomicnc.com/