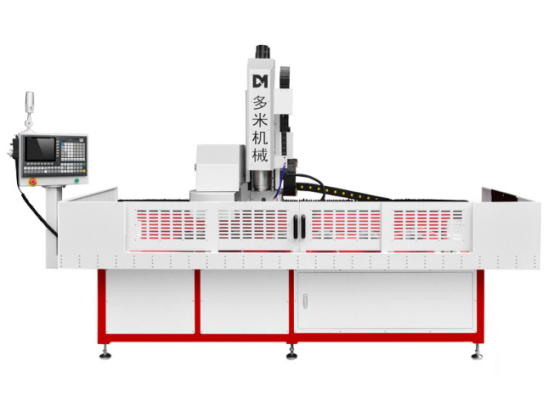

In modern manufacturing industry, gantry CNC drilling machine with its high precision and high efficiency, has become one of the core equipment in the field of precision machining. Especially in the production process of cooling pipes in the data service center, the application of gantry CNC drilling machine runs through the entire processing process to ensure the high quality and consistency of the product. The following is a detailed analysis of the cooling pipe processing technology, focusing on the key role of the gantry CNC drilling machine.

The first process: hot melt drilling

The processing of the cooling pipe begins with the hot melt drilling process. The gantry CNC drilling machine is programmed to accurately perform the interval drilling operation of adjacent holes. In order to avoid material deformation caused by too close to the holes, the numerical control system of the gantry CNC drilling machine will automatically adjust the drilling sequence and spacing according to the preset parameters to ensure the uniform distribution of the holes and the stability of the structure. This process not only improves the processing efficiency, but also lays the foundation for the subsequent process.

The second process: precision detection and data transmission

After the completion of drilling, the precision detector equipped with the gantry CNC drilling machine began to work. The detector accurately measures the height of the product around each hole and transmits the data to the CNC system in real time. This process ensures the accuracy of subsequent processing steps and provides data support for high-quality production of cooling tubes. The intelligent processing ability of the CNC system makes the whole detection and transmission process efficient and error-free.

The third step: milling the surface steps

According to the height and position data transmitted by the detector, the gantry CNC drilling machine enters the milling process. Through precise milling operations, the steps on the surface of the cooling tube are machined to the height required by the design. The CNC system automatically adjusts the milling depth and Angle according to the preset program to ensure the flatness and consistency of the steps. This process is crucial to the final performance of the cooling tube and directly affects its cooling effect in the data service center.

The fourth step: extrusion tapping and lubrication system

After the hole position of the cooling pipe is processed, the gantry CNC drilling machine enters the extrusion tapping process. During tapping, an automatic oil injection lubrication system is available to ensure smooth tap operation while reducing material wear and machining errors. The automatic control of the numerical control system of the gantry CNC drilling machine makes the tapping process efficient and stable, and further improves the processing accuracy of the cooling pipe.

The fifth step: razor deburring

The final step is the razor process, which is used to remove burrs from the stretched bushing on the back of the cooling tube. With precise tool control, the gantry CNC drilling machine ensures that burrs are completely removed while maintaining the smoothness of the cooling tube surface. This process is the final link of the entire processing process to ensure the final quality of the product.

Conclusion

Gantry CNC drilling machine plays an indispensable role in the processing of cooling pipe in data service center. From hot melt drilling to precision detection, to milling, tapping and deburring, each process cannot be separated from the intelligent control of the numerical control system. Through high-precision processing capacity and automated operation, the gantry CNC drilling machine not only improves production efficiency, but also ensures the high quality and consistency of the cooling pipe, providing a solid guarantee for the stable operation of the data service center.

Source of this article: http://www.duomicnc.com/