Precision Deep Drilling Solutions by DUOMI CNC

Deep hole drilling is one of those processes where theory quickly gives way to reality. Tool stability, chip control, thermal balance, and machine rigidity all show their limits the deeper the hole goes. At DUOMI CNC, our CNC deep hole drilling machines are built for this reality—not for brochures.

CNC Deep Hole Drilling Machine Manfacturer

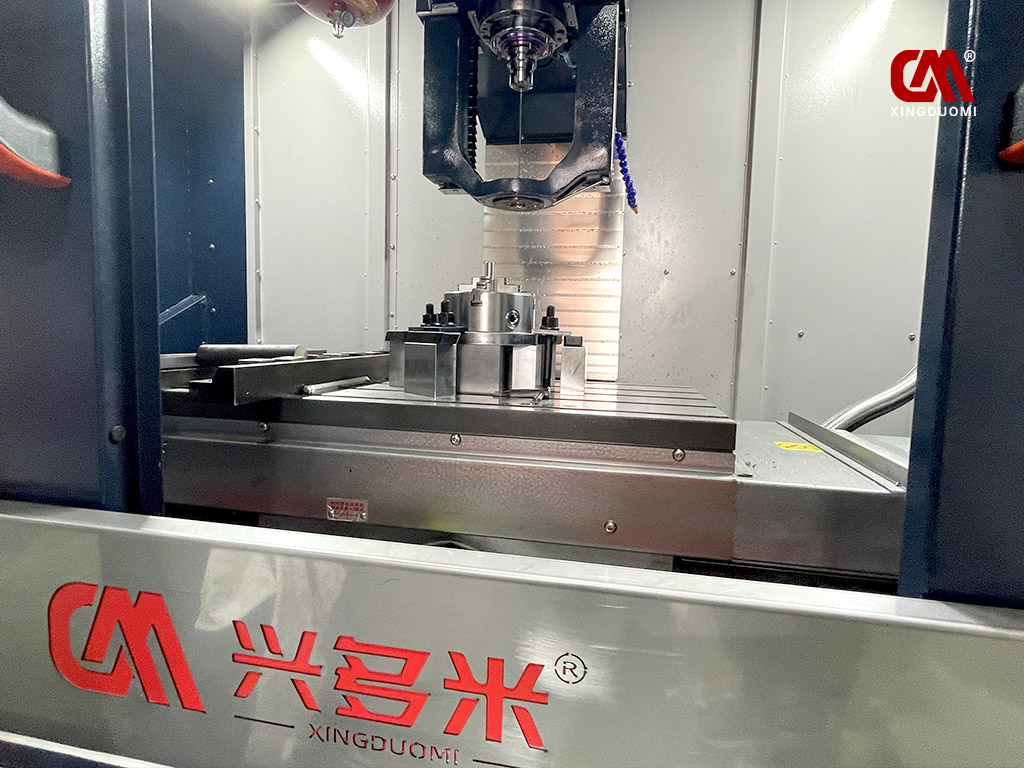

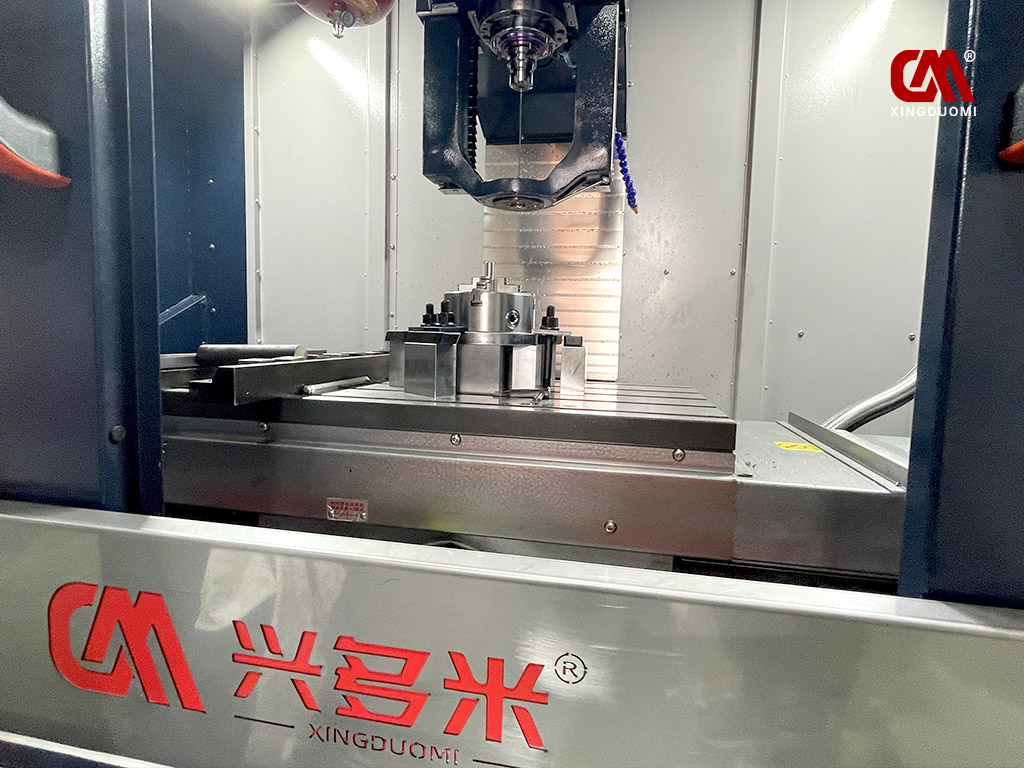

Built for Depth, Not Just Diameter

A true cnc deep hole drilling machine must remain stable as drilling depth increases and tolerance windows narrow. DUOMI CNC designs its machines with reinforced structures and carefully balanced motion systems so straightness, roundness, and surface finish stay consistent, even in long drilling cycles.

From small-diameter deep holes to larger, high-aspect-ratio drilling tasks, the machine maintains control where conventional equipment begins to struggle.

Control That Works the Way Operators Think

The CNC system is selected for clarity and reliability rather than complexity. Operators can focus on the drilling process itself—feed rates, depth control, and tool behavior—without fighting the interface. This approach shortens setup time and reduces human error, especially in repeat production.

For shops handling frequent deep hole drilling CNC jobs, ease of operation quickly translates into real productivity.

Stability You Can Measure

Structure matters more than speed in deep drilling. DUOMI CNC machines use a rigid base and column design to minimize vibration and deflection during long drilling strokes. The result is smoother cutting action, improved tool life, and predictable hole quality.

This stability is especially important for applications involving hardened steels, stainless steel, or thick plate materials.

Designed for Real Cutting Conditions

Deep hole drilling is rarely clean or forgiving. Coolant pressure, chip evacuation, and thermal behavior all affect the final result. DUOMI CNC builds each deep hole drill machine to support continuous cutting with controlled heat and efficient chip removal, helping maintain surface finish and dimensional accuracy throughout the process.

One Machine, Many Applications

Customers use DUOMI CNC equipment across a wide range of industries and materials:

Automotive shafts and structural components

Mold and die plates

Hydraulic and pneumatic parts

Energy and industrial machinery

Stainless steel and carbon steel plates

Whether the requirement is straight deep drilling or combined drilling and finishing operations, the machine adapts to the application rather than forcing compromises.

Manufacturing, Not Trading

DUOMI CNC is a manufacturer. Machines are assembled, tested, and calibrated in-house before delivery. Each CNC deep hole drilling machine is checked for accuracy and motion consistency so it performs as expected on the shop floor, not just during acceptance testing.

This hands-on approach allows us to adjust machine configuration based on real production needs, not assumptions.

A Practical Investment for Long-Term Use

A deep drilling machine earns its value over time. Consistent hole quality reduces rework. Stable cutting extends tool life. Predictable operation shortens learning curves for operators. These factors matter far more than headline specifications once the machine is in daily use.

That is the mindset behind every DUOMI CNC deep hole drilling solution.

Talk to DUOMI CNC

If your production requires a dependable cnc deep hole drilling machine for thick materials, long depths, or tight tolerances, DUOMI CNC is ready to discuss your application.

Tell us your material, hole diameter, depth, and production volume. We will focus on what makes the process work—on the shop floor, every day.

DUOMI CNC

Deep hole drilling machines built for real manufacturing conditions.