As labor costs continue to rise and delivery timelines become increasingly demanding, manufacturers are under constant pressure to optimize production efficiency. A well-configured CNC drilling and tapping machine provides a direct solution by combining multiple machining steps into one streamlined process.

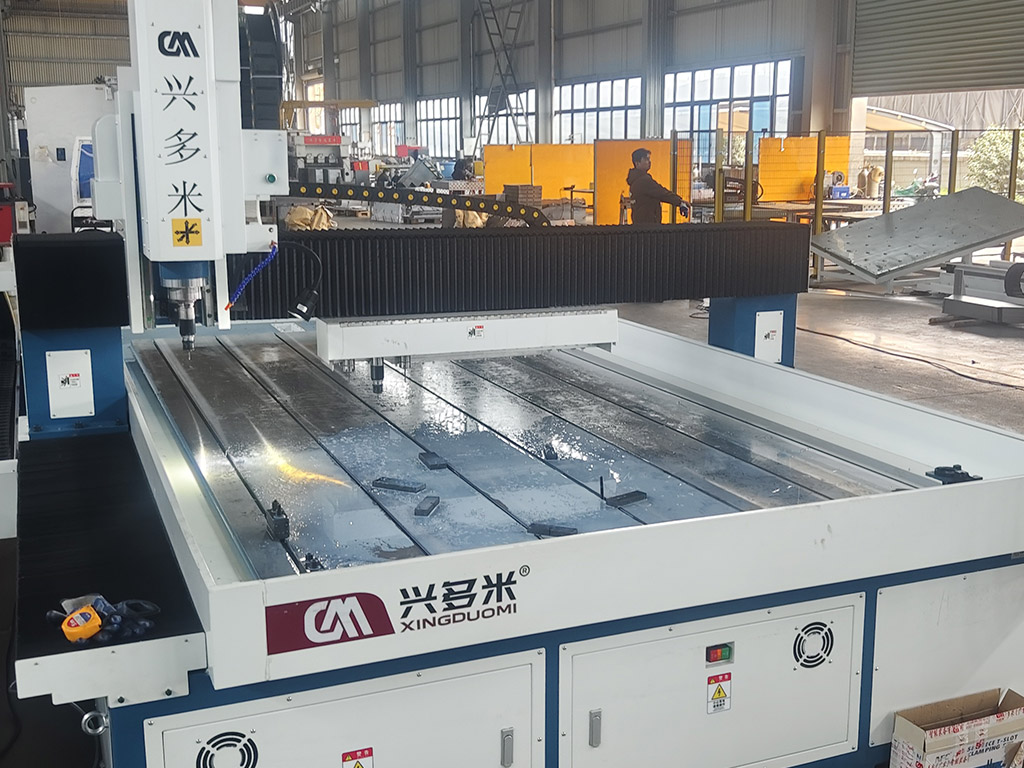

Gantry Type CNC Drilling and Tapping Machine

Traditional drilling followed by manual or semi-automatic tapping often requires repeated positioning, tool changes, and operator intervention. This not only slows down production but also introduces variability in thread quality. CNC drilling and tapping machines eliminate these inefficiencies through fully automated cycle control.

DUOMI CNC develops CNC drilling and tapping machines specifically for high-throughput production environments. Multi-spindle configurations, automated tool management, and programmable machining sequences enable multiple holes to be drilled and tapped simultaneously or sequentially within a single setup.

From a cost perspective, automation significantly reduces dependence on skilled manual labor while improving consistency across large production batches. Once a program is verified, the machine can operate continuously with minimal supervision, ensuring predictable output and reduced scrap rates.

Additionally, DUOMI CNC machines are designed with ease of maintenance in mind. Integrated lubrication systems, robust electrical layouts, and standardized components help minimize downtime and simplify routine servicing. This directly translates into higher machine utilization and lower long-term operating costs.

For companies focused on scaling production while maintaining tight quality control, investing in a CNC drilling and tapping machine from DUOMI CNC is a strategic move toward sustainable manufacturing growth.